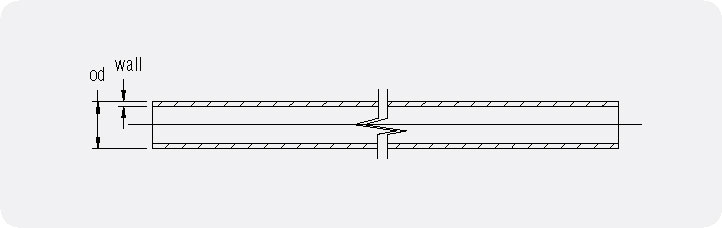

Cardinal UHP 20FT Stick Tubing is engineered for ultra-high purity (UHP) applications where contamination control is critical. Ideal for industries like semiconductor manufacturing, pharmaceuticals, biotechnology, and chemical processing, this tubing ensures the clean, reliable transport of high-purity gases and chemicals.

Manufactured from 316/316L stainless steel or Hastelloy C22, it offers exceptional corrosion resistance, durability, and a smooth, non-reactive inner surface. Each tube undergoes rigorous cleaning and surface finishing to minimize particle generation and maintain system integrity.

Available in diameters from 1/8” to 4”, Cardinal UHP stick tubing meets stringent industry standards including SEMATECH, FDA, and GMP, making it suitable for cleanroom and sterile environments. Its robust construction withstands extreme temperatures and pressures, ensuring long-term reliability in demanding UHP systems.

OUR STICK TUBING COMES IN 20FT LONG STICK FORMAT. QTY IS PER 20FT STICK. IT IS SHIPPED VIA LTL FREIGHT IN A 21FT LONG WOODEN CRATE OR PVC TUBE. AFTER CHECKOUT, WE WILL CONTACT YOU WITH A SEPARATE FREIGHT QUOTE THAT MUST ALSO BE PAID BEFORE THE ORDER CAN BE FULLY PROCESSED. A GREAT ALTERNATIVE FOR CHEAPER SHIPPING WOULD BE OUR UHP Coil Tubing. SAME STRINGENTLY CLEANED AND CERTIFIED TUBING BUT IN COIL!

Feel free to Request a Quote or visit Contact Us with any Questions!

TECH 10

- Chemically polished with an average surface roughness of 25 µin / 0.63 µm Ra.

- High quality ASTM 269 and ASTM 270 316L SS tubing

- Controlled sulfur for consistent weldability.

- Exceeds CFOS CGA G4.1 cleaning.

- Fully passivated with nitric acid.

- Rinsed with DI water, purged with filtered nitrogen, capped and individually bagged in heat sealed polyethylene.

- Used for analyzer sample lines, O2 piping (CFOS), medical gas distribution and vent lines.

- Cleaned to ASTM G93-96 Level A.

TECH 20

- Chemically polished with an average surface roughness of 15 μin / 0.20 μm Ra.

- High quality ASTM 269 and ASTM 270 316L SS tubing.

- Low particulate cleaning.

- Final cleaning and packaging performed in a cleanroom.

- DI water final rinse, purged with filtered nitrogen until dry, capped and individually bagged in heat sealed polyethylene.

- Used for general high purity systems, such as high grade analyzer lines, compressed dry air, argon, nitrogen and other inert bulk gas services.

- Cleaned to ASTM G93-96 Level A.

TECH 50

- Electropolished with an average surface roughness of 7 μin / 0.18 μm Ra.

- 316L SS tubing meets ASTM specifications for consistent physical, dimensional and chemical composition.

- Restricted sulfur content insures consistent weldability and low non-metallic inclusions.

- Final cleaning and packaging performed in a Class 10 cleanroom.

- 0.1 μ filtered 18 Megohm 60°C DI water rinse until effluent surpasses 17.5 Megohm.

- Dried with 0.005 μ filtered 120°C Nitrogen.

- Ends are sealed by pressing LDPE caps over polyamide nylon film.

- Individually double bagged in heat sealed polyethylene.

- Subjected to numerous quality verification tests including: particle and moisture analysis, SEM, ESCA and Auger.

- Used for ultra high purity gas distribution systems.

TG22

- Hastelloy® C22 – a nickel chromium alloy is extremely resistant to pitting and crevice corrosion.

- Surface roughness of 20 μin / 0.5 μm Ra.

- Chemically polished and passivated in nitric acid bath followed by a DI water rinse.

- Final cleaning and packaging performed in a Class 10 cleanroom.

- Rinsed with 0.1 μ filtered 18 Megohm 60°C DI water.

- Dried with 0.005 μ filtered 120°C Nitrogen.

- Ends are sealed by pressing LDPE caps over polyamide nylon film.

- Individually double bagged in heat sealed polyethylene.

- Verified quality by particle and moisture testing.

- Used for high purity distribution of highly corrosive gasses.